Industrial Maintenance – Creating a Path Forward for Students

Traditionally, the world of education has orbited around four core academic subjects – Reading, Math, Science, and History. Other subjects have branched off from the core four as students’ options for classes expanded as they entered high school. Some high schools offer creative writing or contemporary issues or statistics, but a large emphasis has alway been placed on these four academic disciplines.

For nearly 100 years, however, a field of necessary education has been evolving out of the educational spotlight. Career and Technical Education (CTE) classes have been in public schools in some form since the 1920’s, but have only recently demanded more attention because of the skills they teach students – skills that are much needed in the workforce today.

At Haywood High School (HHS), options and opportunities abound in the CTE program. Students can not only build foundations for industrial maintenance, business management, and health science, but they can also receive post-secondary credit in some of those fields, as well. Many of the CTE programs at Haywood High School offer dual-enrollment options for students.

Leading the Industrial Maintenance branch of the CTE program at HHS is James “Skipper” Moss. Before arriving at HHS to be part of the CTE program, Skipper taught at The Tennessee Colleges of Applied Technology (TCAT).

TCAT has 27 campuses across the state of Tennessee and offers a variety of programs on the post-secondary level geared toward developing skills for students to enter the workforce in areas that range from graphic design to welding technology to industrial maintenance repair.

While at TCAT, Skipper taught Industrial Maintenance Repair, but for the last 12 years, he has been helping HHS students get a head start on their careers by teaching the same principles and skills to them that he taught while at TCAT.

While at TCAT, Skipper taught Industrial Maintenance Repair, but for the last 12 years, he has been helping HHS students get a head start on their careers by teaching the same principles and skills to them that he taught while at TCAT.

Skipper teaches three levels of his Industrial Maintenance class at HHS. The first level is for beginning students in the program and focuses very much on safety training.

“The program is divided into three levels. On level one, we work on a lot of safety training – how to work with electricity; how to work with heights; how to avoid pinch-points,” he explained.

The most important aspect of the level one training, however, is that students can receive their OSHA 10 certification.

OSHA stands for Occupational Safety and Health Administration and is a necessary entity in the industrial world. Receiving this certification allows students to have an edge on other job applicants should they decide to pursue a career in any type of industry as soon as they leave high school.

“An important part of this safety training is that students are able to get their OSHA 10 card,” Skipper said. “The OSHA training is a prerequisite to getting hired for any industrial occupation, so students already have an advantage over other job applicants once they leave this program.”

“The OSHA training is a prerequisite to getting hired for any industrial occupation, so students already have an advantage over other job applicants once they leave this program.”

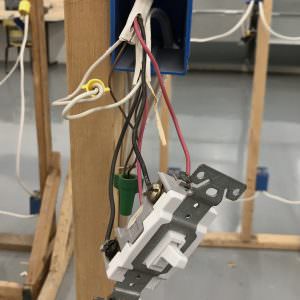

Once students have their OSHA certification and level one safety training behind them, they can begin to really dive into the nuances of the industrial maintenance program. The program deals with specialized skills such as electrical wiring and alternating and direct currents (AC/DC). In level two of the program, students begin to put theory into practice.

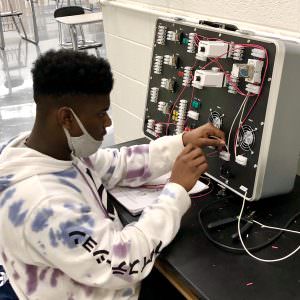

“During the second year of the program we go through a lot of AC/DC fundamentals and electrical safety. We start designing and wiring circuits and then wire them on circuit board trainers,” Skipper said. “In level three, there’s a little more safety training but we really get into a lot more AC three-phase and single-phase wiring. We work with control panels and automated controls. This is all hands-on work,” Skipper explained.

Because the most important aspects of the class are learned by doing the hands-on work, students are provided electrical circuit boards to actually perform the work they would be doing in a factory or industrial plant.

Aiden Sloan is a student who is in his third year in the Industrial Maintenance program. He believes the work is challenging, but is also an enjoyable experience.

“Sometimes it’s really challenging. The hardest part is remembering what certain symbols represent and what each part does,” he said.

While the actual implementation of the learning can be challenging, the learning leading up to the hands-on work helped him understand quicker.

“Once you get to the machine, it should be pretty simple because we’ve been learning about it by reading it,” Aiden explained.

Like many students in the program, Aiden plans on attending TCAT when he graduates from HHS and will already have several classes completed when he starts.

Skipper knows how important it is for his students to have an advantage.

“This is a dual-enrollment class with TCAT. We have a good relationship with them, and I send them the best students I have over there,” Skipper said. “Some of my students are already halfway through the TCAT program when they leave here.”

Training students with a CTE skill set has always been a priority at HHS. Having a teacher like Skipper, who has previously taught at TCAT, only strengthens the program and allows students to be exposed to the work early on and be ready for more intensive training once they leave high school. However, a few months ago, the need for that training and these particular types of skills became even more prevalent with the announcement of Blue Oval City and Ford coming to Haywood County.

Training students with a CTE skill set has always been a priority at HHS. Having a teacher like Skipper, who has previously taught at TCAT, only strengthens the program and allows students to be exposed to the work early on and be ready for more intensive training once they leave high school. However, a few months ago, the need for that training and these particular types of skills became even more prevalent with the announcement of Blue Oval City and Ford coming to Haywood County.

“With Ford coming, I’m encouraging the kids right now to get involved in this program. I’m encouraging them to go to TCAT when they leave HHS and take any supplemental training they can get, so that when those doors open or job postings pop up, they’re ready,” Skipper said.

Beyond the technical training students are receiving as it relates to electrical wiring and industrial maintenance, soft skills are also a necessity when it comes to acquiring and keeping a job when students leave high school. Positive attributes like punctuality and a strong work ethic are just as important to employers as skills in wiring or routing circuits.

“Aside from the technical skills we teach our students here, we also have to teach our students soft skills that are necessary to get and keep a job. We have to teach students to be on time, stay off their phones, and pay attention. Those are issues of courtesy, but also could affect safety in a workplace if not practiced,” Skipper explained.

Skipper is at an age where he could retire soon if that is something that he would like to do, but he sees so much promise and opportunity with the arrival of Blue Oval City.

“This area is about to change with Blue Oval City. Most of that plant will be automated – robots and automated controls- but there will be a lot of people needed to maintain that equipment. I know they’re going to build a TCAT on that campus. There’s so much that someone will need to know to be able to do that work, and that’s what we’re teaching our students here already. There’s going to be a huge demand for workers at Ford to keep the machinery working the right way, and students here are already getting the foundations for that training and that work,” he said.

“There’s going to be a huge demand for workers at Ford to keep the machinery working the right way, and students here are already getting the foundations for that training and that work.”

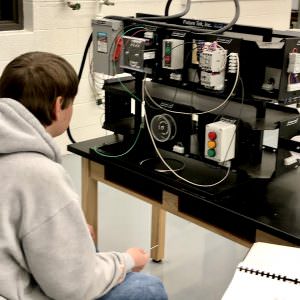

Because of that and the work he sees his students learning and perfecting, Skipper wants to see the work pay off for them. He sees it in students like Caleb Given who is in his third year of the program and learns best while he’s doing the work.

“I started the program my sophomore year because I didn’t know about the program when I was a freshman. I’m about to graduate now and then will be going to TCAT next fall,” Caleb said as he sat in front of a circuit board. “This board was confusing and it took me several weeks to really figure it out, but once I did, it became very easy. I learn better by actually doing the work rather than reading about it or hearing it.”

And, in the end, that is exactly what the Industrial Maintenance Program at Haywood High School is all about – allowing students to develop a skill they can learn by doing the work that will continue to support them as an adult.

“I’d really like to see some of these kids go out to the new plant and go to work. I’d like to see them develop those skills here and take them to Ford, or anywhere for that matter, several years later. That’s what this is all about, really. It’s about giving students a skill or skills they can use to make a career.”

“That’s what this is all about, really. It’s about giving students a skill or skills they can use to make a career.”